VYNOVA

PVC - COMMERCIAL INFORMATION

WHY BUY FROM VYNOVA

Over 50 years of experience in manufacturing and supplying consistently high-quality PVC resins.

Three manufacturing plants ideally located within proximity to major European markets.

Highly reliable operations and excellent supply chain solutions.

Experienced sales and technical support teams dedicated to building strong and effective partnerships with all our customers.

PVC GRADE PORTFOLIO

At Vynova, we produce a comprehensive range of suspension PVC resins suitable for a variety of industrial and consumer applications. Products manufactured from our PVC resins bring water and light into our homes, provide comfort while reducing energy use and improve the quality of our daily lives.

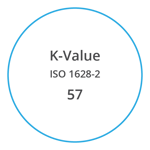

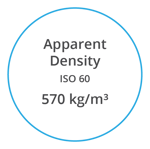

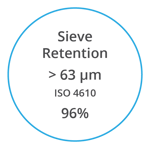

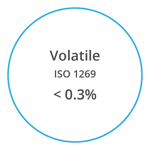

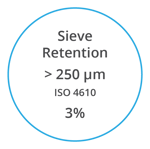

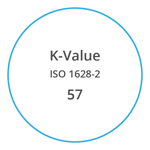

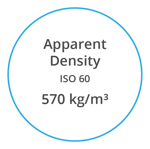

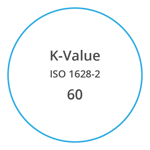

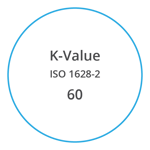

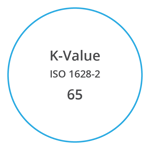

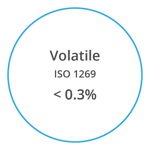

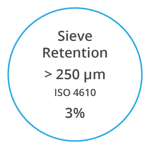

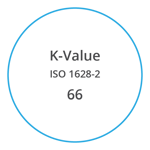

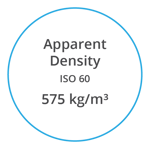

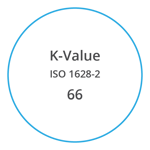

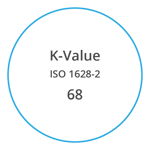

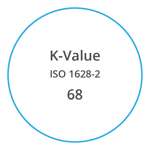

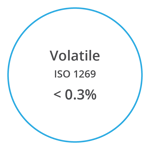

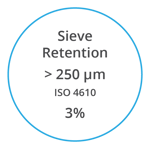

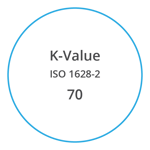

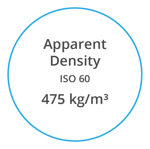

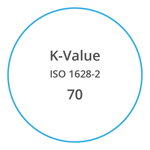

With K-values (a measure of the molecular weight) ranging from 57 to 70, our PVC resins can be blended with additives such as plasticisers, thermal and UV stabilisers, fillers, pigments, impact modifiers and others. This makes PVC one of the most versatile polymers, extensively used across a broad range of industrial and consumer applications.

Discover below which product best fits your business needs.

VYNOVA™ S5730 is a low molecular weight and low porosity vinyl chloride homopolymer produced by a suspension process. After mixing with appropriate additives, VYNOVA™ S5730 is typically recommended and suitable for extrusion, calendering and injection blow

- Films for packaging or consumer goods

- Compact foamed sheets and profiles

- Foamed core pipes and fittings

- Bottles

VYNOVA™ S5702 is a low molecular weight and low porosity vinyl chloride homopolymer produced by a suspension process. After mixing with appropriate additives, VYNOVA™ S5702 is typically recommended and suitable for extrusion, calendering and injection blow

- Rigid films for medical, food or consumer goods packaging

- Compact and foamed sheets

- Foam core pipes and pipe fittings

- Injection

mouldings , including housing - Bottles

VYNOVA™ S5902 is a low molecular weight and low porosity vinyl chloride homopolymer produced by a suspension process. After mixing with appropriate additives, VYNOVA™ S5902 is typically recommended and suitable for extrusion and calendering of PVC articles such as:

- Rigid films for medical, food or consumer goods packaging

- Compact and foamed sheets

- Compact and foamed profiles

- Foam core pipes and fittings

- Flooring

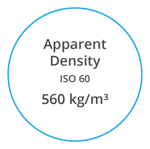

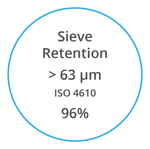

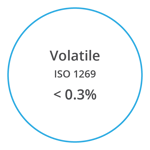

VYNOVA™ S6030 is a low molecular weight and low porosity vinyl chloride homopolymer produced by a suspension process. After mixing with appropriate additives, VYNOVA™ S6030 is typically recommended and suitable for extrusion and calendering of PVC articles such as:

- Rigid films for medical, food or consumer goods packaging

- Compact and foamed sheets

- Compact and foamed profiles

- Foam core pipes and fittings

- Flooring

VYNOVA™ S6202 is a low molecular weight and low porosity vinyl chloride homopolymer produced by a suspension process. After mixing with appropriate additives, VYNOVA™ S6202 is typically recommended and suitable for extrusion and calendering of PVC articles such as:

- Compact and foamed sheets

- Compact and foamed profiles

- Foam core pipes and fittings

- Flooring

VYNOVA™ S6502 is a high molecular weight and high porosity vinyl chloride homopolymer produced by a suspension process. After mixing with appropriate additives, VYNOVA™ S6502 is typically recommended and suitable for extrusion, calendering of both rigid and flexibles PVC articles such as:

- Profiles

- Sheets & Films

- Compounds

- Flooring

VYNOVA™ S6630 is a medium molecular weight and medium porosity vinyl chloride homopolymer produced by a suspension process. After mixing with appropriate additives, VYNOVA™ S6630 is typically recommended and suitable for extrusion of PVC articles requiring excellent mechanical properties such as:

- Window Profiles

- Rigid Profiles

- Pipes

VYNOVA™ S6706 is a medium molecular weight and medium porosity vinyl chloride homopolymer produced by a suspension process. After mixing with appropriate additives, VYNOVA™ S6706 is typically recommended and suitable for extrusion of PVC articles requiring excellent mechanical properties such as:

- Window Profiles

- Rigid Profiles

- Pipes

VYNOVA™ S6806 is a medium molecular weight and medium porosity vinyl chloride homopolymer produced by a suspension process. After mixing with appropriate additives, VYNOVA™ S6806 is typically recommended and suitable for extrusion of PVC articles requiring excellent mechanical properties such as:

- Window Profiles

- Rigid Profiles

- Pipes

VYNOVA™ S6830 is a medium molecular weight and medium porosity vinyl chloride homopolymer produced by a suspension process. After mixing with appropriate additives, VYNOVA™ S6830 is typically recommended and suitable for extrusion of PVC articles requiring excellent mechanical properties such as:

- Window Profiles

- Rigid Profiles

- Pipes

VynoKlear is a high molecular weight vinyl chloride homopolymer produced by a suspension process. After mixing with appropriate additives, VynoKlear is typically recommended and suitable for extrusion, calendering or injection

VynoKlear is

- Superior porosity and compatibility with all types of plasticisers;

- Unique transparency,

colour and surface aspect; Absence of antioxidants in the formulation.

These distinctive properties and features make VynoKlear particularly suitable for a variety of high-quality flexible end products e.g.:

- Clear and transparent medical products;

- Waterproofing membranes;

- Innovative flexible goods.

VYNOVA™ S7102 is a high molecular weight and high porosity vinyl chloride homopolymer produced by a suspension process. After mixing with appropriate additives, VYNOVA™ S7102 is typically recommended and suitable for extrusion, calendering or injection moulding of semi-rigid and flexibles PVC articles such as:

- Cling films

- Flexible sheets (Pool liners, Inflatables, Roofing Membranes…)

- Profiles

- Cables insulation and sheathings

- Flooring

ISO CERTIFICATES

THE VYNOVA PVC SALES TEAM

Our PVC sales team provides technical expertise and reliable support for your business needs. If you have questions about our comprehensive range of suspension PVC resins, we will be happy to respond to your enquiry.

Find out how we can positively impact your business. Fill out the form and we will contact you as soon as possible.

You can download our general terms and conditions of sale on the dedicated page.

VINYLS SALES & MARKETING

PVC SALES AND APPLICATION SUPPORT

CONTACT OUR SALES TEAM

Please complete this form for enquiries about our PVC grade portfolio. Your question will be directed to a PVC sales or customer service representative within your region, who will contact you as soon as possible.

By submitting this form I agree